Tube Lasers Cutting Systems Washington

Some things arenít quite as evident until you take a closer look at a fiber laser in operation. Because its beam diameter is often one-third the size of a CO2 beam, a fiber laser has a greater power density than a CO2 laser beam. Not only does this allow the fiber to cut faster, but it also allows it to pierce faster. This smaller beam size also gives the fiber the ability to cut intricate shapes and leave sharp edges. Imagine cutting a company logo out of a tube when the spacing between the logoís letters is 0.035 inch; a fiber can make that cut, while a CO2 laser canít.

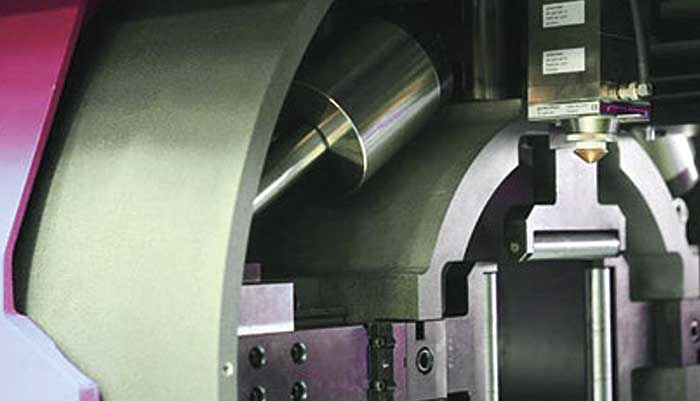

StarFeed can be used as an automated loader/unloader to the StarCut Tube laser cutting machine. It comes in two sizes, S and L. The StarFeed allows you to fully automate dry and wet cutting for tubes of any diameter from 1-20mm. StarFeed L can store 48 tubes and allows processing of oval tubing. Its sensor-controlled gripping unit avoids damage. The result is a substantial increase in productivity.